Screws are the most popular fastener around the world. They help users join multiple objects with ease. Typically, they feature a long shaft and helical threading. However, not all screws are the same. Below are various types of screws.

Today, I present you with my screw-buying guide. You will find screws in many sizes, materials, and shapes. Not to mention, they have different uses. If you are a beginning DIY-er, this ultimate list of screws surely keeps your confusion at bay.

Screw and Screw Head Purchasing Guide

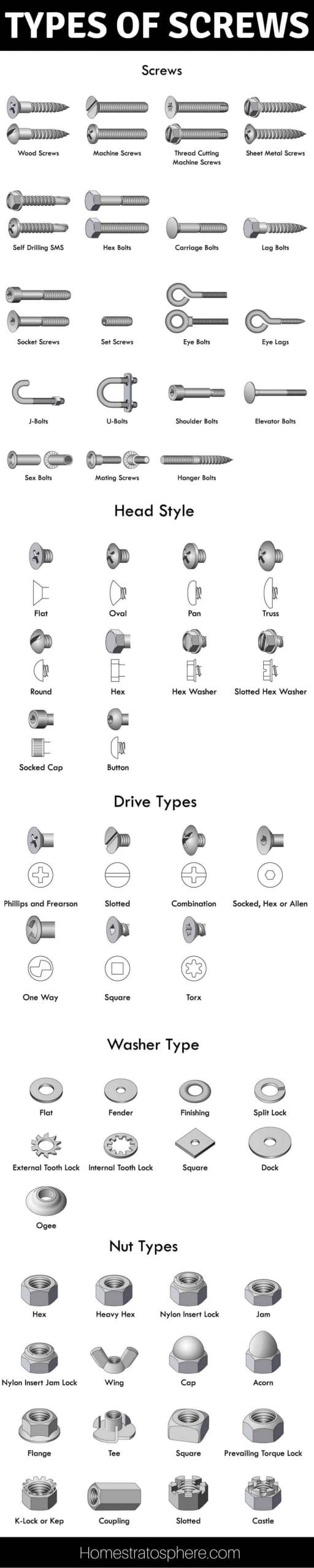

As the chart shows, there are differences between the screw shapes and drives types. By learning about the screws and screw heads, you know the right tools for yours.

The Shapes of Screw Heads

The head shapes of the screws do not only offer aesthetics. They are constructed that way for certain reasons. First, they make you create your project easier. Second, they affect the look of your product.

Countersunk Screw Heads

Like the name sounds, they require a countersinking method to prevent the wood from splitting. Use countersink drill bit or countersink cutter to bore the surface. This process gives your project a professional look.

1. Raised

These screws have dome-like heads. Their shapes are more for decoration. Moreover, they slightly leave their heads outside. Be sure you must do countersinking to prepare the seating of the raised screw heads.

2. Flat

Flat screw heads completely sit flush with the material surface. Therefore, the other things will not catch on them. They are vital if you build your sofa. You can use flat screw head covers to conceal the heads.

They come with varying angles. The 82-degree flat head screws are the standard models. There are flat head screws with shorter heads and longer threads too.

3. Bugle

Bugle heads are mostly utilized on screws designed for both drywall and plasterboard. They look like flat screw heads. The curves underneath the heads prevent the screws from damaging a surface.

Furthermore, bugle screw heads are self-drilling. You do not need to create the proper angles and pilot holes to house them.

Non-Countersunk Screw Heads

These screws have angle fewer heads. Their heads are entirely exposed. Moreover, they do not require you to countersink them.

4. Domed

Domed screw heads are mainly used to create the ottomans. They lend those furniture units a visual appeal.

5. Truss

Truss screw heads are wider than the others are. They have a slightly rounded top and offer a larger bearing surface. You need them when you work with sheet metal.

6. Binding

Binding screws have slightly domed heads. They feature two parts, male and female end. Moreover, they hold together your swatches, bookbinding and leatherworking projects.

7. Flange

These screws are also known as frame screws. Their heads vary widely from hexagonal to circular. They protrude from the circular flanges. Therefore, the screws will remain in their positions.

Combination Screw Heads

Some combination screw heads require countersinking, while some do not. The countersunk screw heads usually employ angular heads. Non-countersunk ones boast heads without angles.

Drive Types of Screw Heads

Different screw head certainly needs a different tool. You will find various shapes on screws. To dig your screws into their place, you must use the right screwdriver. Some screw head drive types are more expensive but they perform better.

8. Hex Internal

The internal hex screws can be installed and removed using the Allen wrench. They lend the furniture a delightful finish.

9. Hex External

These screws have hexed heads that jut out from the surface. Like the internal screws, you need a socket or an Allen wrench to install as well as remove them.

10. Pozidrive

They are similar to the Phillips screws, except they employ more grooves in them. Their grooves resemble a star. Pozidrive screws provide great stability when you apply force.

11. Phillips

Phillips screws have a cross-like drive type. Make sure you do not give them too much force unless you want to strip their heads.

12. Slotted

These screws typically feature one narrow slot for a flat screwdriver. They are likely the cheapest screws. However, they are susceptible to stripping. So, do not over tighten them.

13. Quadrex

Quadrex screws are a cross between square recess and Phillips. Since they have squared drive shape, they will not get broken easily.

14. Star

As the name implies, these screws boast heads that look like stars. The double-square drives comprise two of Robertson’s squares that create an 8-point star.

Furthermore, triple-squares have three Robertson’s squares, forming a 12-point star. They are made for internal car parts.

15. Square Recess

The square recess screws are usually called Robertsons. They include a square center point to avoid stripping. Moreover, they have a self-holding design.

16. TORX

TORX screws comprise a 6-point star in the middle. They are mostly utilized in the electronics manufacturing industry. You will find them on DVD players and computers.

17. TORX Plus

The grooves between star points of TORX Plus screws are relatively shallower than the regular TORX. They enable your screwdriver to contact the heads and apply more force.

18. Tri-Wing

Tri-Wing screws let you put more force on them. Moreover, they offer great security. You cannot install and remove them without a special screwdriver.

Security Screws

These screws are difficult to tamper. They can be found in public spaces such as malls, public restrooms, and waiting rooms.

Additionally, tamper-resistant screws typically have no operable head. Therefore, no one can remove them.

19. Sentinel Screws

The designs of sentinel screws are truly excellent. They work best for expensive fixtures. Thieves cannot remove them.

20. Pin Screws

Pin screws are similar to Phillips screws, but they possess an extra layer of security to avoid easy removal. Their heads have unique pins as well.

21. Two-Hole Screws

Two-hole screws are referred to as spanners. They boast a flat head with two tiny holes. Not only are they amazing for security applications, but also create a good finished look.

More Details

1. To prevent cam comes out, you should choose the right bit for your screw.

2. Do not use a cheap and wrong drill bit. It can cause stripped screws.

3. To remove the damaged screw, you need a stripped screw extractor.

4. Screw heads with several points and grooves are suitable for complicated projects.

5. Stainless steel and titanium screws are more weather-resistant than the aluminum ones.

6. High-performing and specialty screws are relatively more expensive.

7. You can buy screws from online retailers.

You have learned about those types of screws. Since screws are an indispensable part of various projects, you should know their uses. Finally yet importantly, select the right screw materials.